Key Takeaways

Licensed character statues represent a unique intersection of artistic vision and commercial IP management. These stainless steel creations require specialized processes to balance aesthetic demands with brand guidelines. Below are critical insights into their production:

| Aspect | Key Detail | Industry Standard |

|---|---|---|

| Material Selection | 304-grade stainless steel | ASTM A240 |

| Fabrication Method | MIG welding for seamless joints | AWS D1.6 Structural Code |

| Design Phase | 3D modeling with IP holder approvals | CAD precision ±0.5mm |

| Surface Finish | Bead-blasted anti-glare treatment | Ra 1.6–3.2 μm roughness |

"The challenge lies in making Iron Man's armor plates look dynamic while maintaining structural integrity," notes Lucas Rhee, a pioneer in kinetic sculpture techniques. "Each curved panel must withstand 90mph winds yet appear weightless."

Three factors differentiate these sculptures from conventional metalwork:

- IP Compliance Teams: Legal specialists work alongside artists to ensure facial proportions and costume details match licensor specifications

- Weatherproofing Protocols: Despite 304 steel's corrosion resistance, coastal installations require additional passivation treatments

- Modular Assembly: Pre-fabricated sections enable museum-grade installations within 72 hours

For public art commissioners, consider:

- Request certified weld procedure specifications (WPS) documents

- Verify licensor's style guide adherence through 3D render cross-checks

- Schedule seasonal electropolishing to maintain reflectivity

This manufacturing paradigm transforms temporary pop culture motifs into enduring civic landmarks through calculated material science and copyright negotiations. From initial concept to final installation, every weld bead and contour curve serves both artistic and contractual obligations simultaneously.

Stainless Steel Sculpture Manufacturing Process

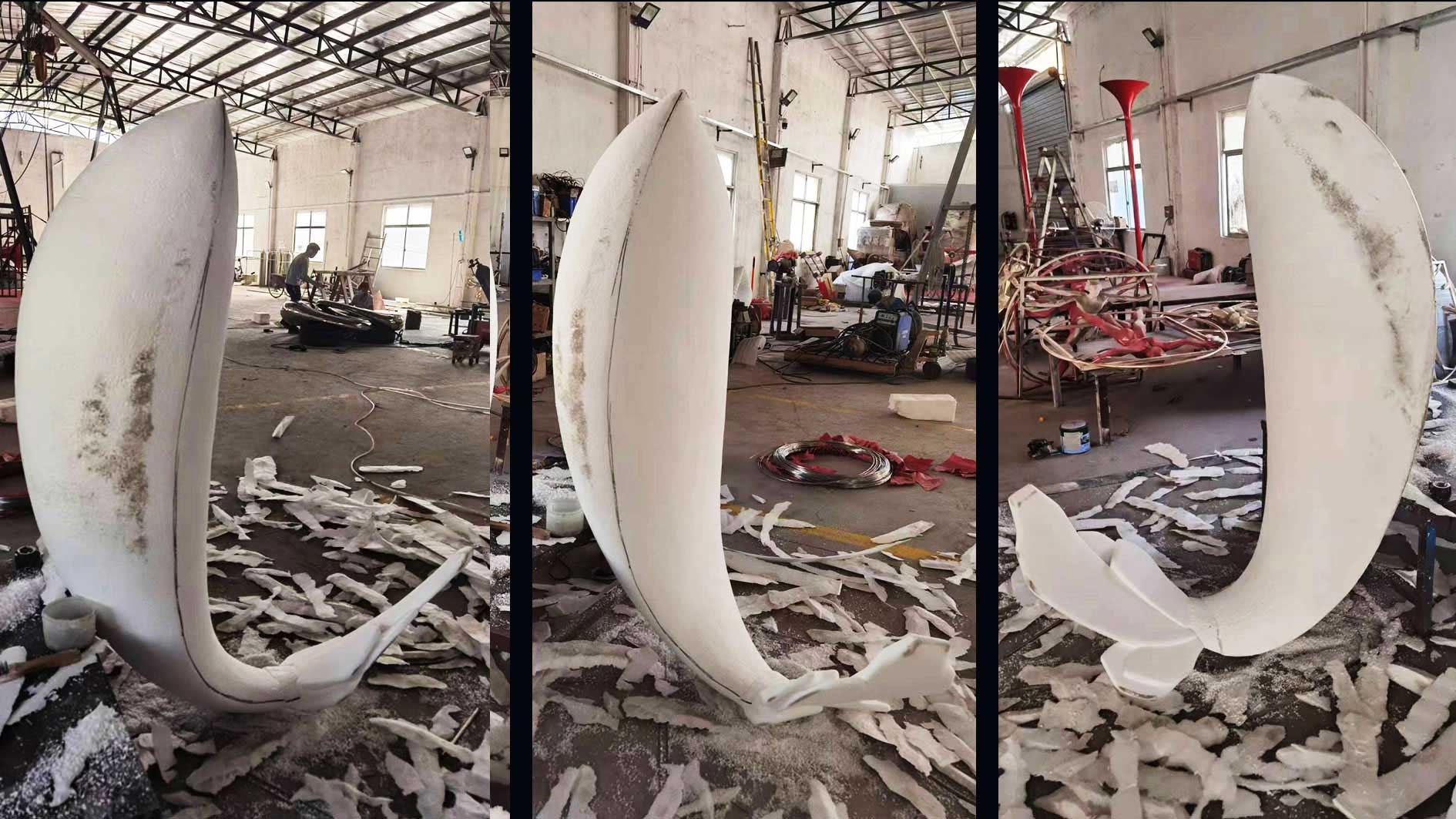

The creation of licensed character statues from stainless steel begins with precise digital modeling, where 3D artists translate cultural icons into scalable designs. Industrial-grade 304 stainless steel is selected for its corrosion resistance and structural integrity, ensuring sculptures withstand outdoor conditions for decades. Fabricators employ CNC plasma cutting to shape flat metal sheets into intricate components, followed by MIG welding to assemble parts with minimal visible seams.

Artisans then grind and polish surfaces to achieve reflective finishes, often using progressive grit sanding tools to eliminate tool marks. For complex curves, hydraulic presses mold heated steel into organic shapes, balancing artistic expression with geometric accuracy. Quality checks involve stress-testing joints and verifying proportions against licensed brand specifications, ensuring each piece aligns with intellectual property guidelines.

This fusion of industrial methods and artistic vision allows mass-produced durability to coexist with hand-finished details, meeting both commercial demands and aesthetic standards. The process bridges pop culture’s fleeting trends with stainless steel’s permanence, transforming fictional figures into enduring public art.

Licensed Characters Meet Metal Artistry

The fusion of licensed characters with stainless steel sculpture represents a unique intersection of intellectual property and industrial craftsmanship. Legal agreements between artists and rights holders allow iconic figures from films, comics, and animation to be reimagined as durable metal artworks. This process begins with meticulous 3D modeling to translate two-dimensional designs into structural forms that maintain brand identity while meeting engineering demands.

Specialized workshops employ Cartoon sculpture techniques to balance artistic expression with trademark compliance, ensuring features like facial expressions or costume details align with official guidelines. Architectural-grade 304 stainless steel is favored for its corrosion resistance, enabling these pieces to withstand outdoor display in theme parks or public spaces. Advanced methods such as laser cutting and TIG welding preserve intricate contours, transforming pop culture symbols into heirloom-quality installations.

Collaborations between sculptors and licensors often involve iterative prototyping to refine proportions and posture, ensuring the final work resonates emotionally while adhering to material constraints. The result bridges nostalgia and permanence—ephemeral characters gain physical form through a medium built to endure decades of exposure.

Industrial Techniques in Artistic Sculpting

The fusion of industrial methods with sculptural artistry has redefined how licensed characters materialize as stainless steel monuments. Unlike traditional hand-carving, modern fabrication employs precision tools like CNC plasma cutters to shape 304-grade steel into intricate forms, ensuring millimeter accuracy for features like facial expressions or costume details. MIG welding, a staple in automotive manufacturing, becomes pivotal here—its controlled arcs fuse metal panels seamlessly, creating smooth joints that withstand outdoor exposure.

Collaborations between artists and industrial engineers bridge aesthetic vision with structural integrity. For instance, wind load calculations inform internal steel framing, while powder coating systems apply fade-resistant finishes. This technical rigor doesn’t stifle creativity; instead, it enables IP character sculptures to maintain brand-recognizable silhouettes while achieving architectural durability. The process mirrors aerospace prototyping, where 3D-scanned models undergo stress simulations before final fabrication—transforming beloved pop culture figures into timeless steel landmarks.

Artisan Partnerships for Iconic Statues

The creation of licensed character statues relies on collaborations between skilled artisans and industrial manufacturers, blending artistic vision with technical precision. Artists specializing in pop culture iconography work closely with metal fabrication experts to translate 2D designs into three-dimensional steel forms. This partnership ensures that details like facial expressions or costume elements—critical for character recognition—are preserved through CNC plasma cutting and hand-finishing techniques. For example, sculptors might refine weld seams to mimic organic textures, while engineers ensure structural integrity using architectural-grade 304 stainless steel.

Such collaborations often extend beyond aesthetics, addressing challenges like weather resistance for outdoor installations or weight distribution for large-scale pieces. While stainless steel dominates this niche, alternative materials like Fiberglass sculpture offer lighter solutions for temporary displays. By merging IP compliance with industrial-grade craftsmanship, these partnerships transform fleeting pop culture moments into enduring physical artifacts, balancing corporate licensing requirements with the artisan’s creative interpretation.

304 Steel Durability in Pop Culture Art

The integration of 304 stainless steel in licensed character statues reflects a deliberate alignment between material science and cultural preservation. Unlike conventional metals, this architectural-grade alloy resists corrosion, oxidation, and structural degradation—qualities critical for outdoor installations exposed to weather cycles. Theme parks, urban plazas, and public memorials increasingly rely on 304 steel’s stability to maintain the visual fidelity of pop culture icons, from superheroes to animated figures, ensuring their details remain sharp despite decades of environmental stress.

This durability also supports the storytelling essence of these artworks. A Realistic sculpture of a beloved character must retain its expressive contours and polished surfaces to resonate with audiences, a feat achievable only through metals engineered for longevity. By pairing 304 steel’s resilience with precise fabrication methods, artists safeguard intellectual property integrity while transforming fleeting trends into enduring landmarks. The material’s adaptability to finishes—from mirrored brilliance to brushed textures—further bridges creative vision with real-world demands, solidifying its role as the backbone of modern pop culture artifacts.

From 3D Design to Steel Reality

The journey from digital concept to tangible sculpture begins with advanced 3D modeling software, where artists refine licensed characters into precise geometric forms. Using tools like CAD or sculpting programs such as ZBrush, creators balance artistic expression with structural integrity—ensuring features like flowing capes or dynamic poses translate seamlessly into steel. Once approved by intellectual property holders, these models undergo digital slicing, breaking the design into layered templates for fabrication.

Industrial-grade CNC plasma cutters then carve 304 stainless steel sheets into puzzle-like components, prioritizing efficiency and minimal material waste. Skilled welders assemble these pieces using MIG (Metal Inert Gas) techniques, fusing joints with durability matching architectural standards. Critical details, such as facial expressions or emblematic accessories, often require hand-forging to preserve authenticity. Throughout this phase, collaboration between 3D artists and metalworkers ensures the final sculpture mirrors its virtual blueprint while meeting load-bearing requirements for public installations. This technical synergy transforms pop culture icons into enduring, weather-resistant monuments.

MIG Welding in Sculpture Fabrication

MIG (Metal Inert Gas) welding serves as a cornerstone technique for assembling stainless steel character statues, combining industrial precision with artistic requirements. This method uses a continuous wire electrode shielded by an argon gas mixture, creating strong, clean joints critical for structural integrity. Sculptors favor MIG welding for its ability to fuse 304-grade steel without compromising the metal’s corrosion resistance—a necessity for outdoor installations featuring licensed pop culture figures.

The process begins by aligning laser-cut steel components, often shaped using CNC machinery based on 3D models. Welders strategically apply heat to bond intricate contours, such as a superhero’s dynamic pose or a cartoon mascot’s curved features, while minimizing visible seams. Unlike traditional sculpting methods, MIG welding ensures uniform material distribution, preventing weak points in load-bearing areas like extended arms or elevated bases. Post-welding grinding and polishing then refine surfaces to match the original digital design’s sleek aesthetic.

Artisans particularly value this technique for its adaptability across scales—whether crafting life-sized statues or miniature collectibles. By maintaining temperatures below 1,500°F, the process preserves the steel’s crystalline structure, ensuring decades of weather resistance. This combination of technical control and material science transforms temporary cultural icons into permanent stainless steel landmarks.

Intellectual Property in Modern Metalwork

While stainless steel sculpting relies on industrial techniques, creating licensed character statues introduces complex legal considerations. Manufacturers must secure formal agreements with copyright holders to reproduce trademarked figures, ensuring designs adhere to strict brand guidelines. This process often involves collaboration between artists, legal teams, and intellectual property owners to balance creative interpretation with corporate mandates.

Precision in replicating features—from a superhero’s emblem to an animated character’s proportions—becomes both an artistic challenge and a contractual obligation. Fabricators use 3D modeling software to achieve accuracy, with IP holders frequently reviewing digital prototypes before approving metal fabrication. Such oversight guarantees that final sculptures maintain brand integrity while meeting structural requirements for public installation.

The use of architectural-grade 304 steel also serves IP interests by ensuring decades of outdoor display without corrosion-induced distortion. Licensing agreements typically mandate material specifications, linking technical durability to the long-term preservation of copyrighted imagery. This synergy between legal frameworks and metallurgical science transforms transient pop culture symbols into enduring civic landmarks.

Cultural Icons Transformed Through Steel

The fusion of pop culture and stainless steel sculpture redefines how audiences interact with familiar characters. By translating animated or cinematic figures into three-dimensional metal forms, artists bridge nostalgia with industrial innovation. This process begins with digital sculpting tools that reinterpret 2D designs into layered 3D models, ensuring proportions align with both artistic vision and structural feasibility.

Using architectural-grade 304 stainless steel, these statues withstand outdoor exposure while retaining refined details—from a superhero’s emblem to a cartoon mascot’s expression. Collaborations between licensors and metalworkers ensure legal compliance without compromising creative integrity, balancing trademark guidelines with artistic interpretation. For example, a fluidly posed anime character might gain reinforced joints through TIG welding, maintaining dynamic posture against wind loads.

Such transformations extend beyond aesthetics. A statue’s reflective surface interacts with sunlight, creating shifting visual effects that mirror the evolving nature of cultural relevance. This interplay between permanence and adaptability reflects modern storytelling—where timeless characters persist through changing mediums. As these steel icons populate public spaces, they invite tactile engagement, turning passive fandom into physical interaction.

Conclusion

The creation of licensed character statues in stainless steel represents a unique intersection of artistic vision and industrial precision. These sculptures not only immortalize beloved pop culture figures but also demonstrate how modern manufacturing techniques, such as MIG welding and 3D modeling, elevate traditional craftsmanship. Collaborations between artists and manufacturers ensure that each piece adheres to both aesthetic standards and intellectual property guidelines, balancing creative expression with legal compliance.

While 304-grade stainless steel provides the structural integrity needed for outdoor installations and long-term durability, it also challenges artists to adapt their designs to the material’s properties. This dynamic process underscores how industrial methods can coexist with imaginative storytelling. Ultimately, these statues serve as cultural touchstones, transforming fleeting trends into lasting monuments that resonate across generations. Their existence reflects a broader shift in public art—one where technical rigor and pop culture nostalgia converge to redefine what modern sculpture can achieve.

Frequently Asked Questions

How does stainless steel enhance character statue longevity?

The chromium in 304-grade stainless steel forms an invisible oxide layer, resisting corrosion and discoloration. This makes sculptures suitable for both indoor displays and outdoor installations exposed to rain or humidity.

What industrial methods ensure precise detailing?

MIG welding allows seamless joins between metal sheets, preserving facial expressions and costume textures. CNC cutting follows 3D models to replicate complex features like flowing capes or intricate armor patterns within 1mm accuracy.

Do artists need special permissions for pop culture figures?

Licensing agreements with intellectual property holders are mandatory before production. Studios often collaborate with copyright agencies to ensure designs align with brand guidelines while incorporating artistic interpretation.

How do weather conditions affect maintenance needs?

While 304 steel resists rust, annual cleaning with pH-neutral solutions prevents dirt buildup. Coastal areas may require biannual inspections to address salt exposure, though structural integrity typically remains intact for 15+ years.

Can these statues be customized for specific venues?

Yes—designers adjust scale and pose based on installation environments. Shopping malls often request interactive poses at 8-10ft heights, while corporate lobbies may prefer smaller, reflective finishes that complement architectural lighting.

What distinguishes licensed statues from generic metal art?

Authenticity certificates and embedded holograms verify official partnerships. These markers protect against counterfeits while ensuring collectors receive artworks meeting both artistic and copyright standards.

ch

ch English

English