Key Takeaways

Designing weather-resistant fiberglass art installations requires balancing material science, structural engineering, and artistic vision. Fiberglass-reinforced polymer (FRP) composites excel in outdoor settings due to their corrosion resistance, lightweight properties, and adaptability to complex shapes. However, achieving longevity demands careful selection of resins (e.g., isophthalic polyester for UV resistance) and reinforcement fabrics (e.g., high-strength woven roving).

“Always prioritize UV-stable resins and gel coats to prevent yellowing and degradation,” advises marine composite expert Dr. Elena Torres. “Outdoor installations face cumulative solar exposure, so material choices must account for decades, not years.”

Structural integrity hinges on integrating load-bearing frameworks during molding, such as aluminum or stainless-steel armatures, to withstand wind and temperature fluctuations. Protective coatings—like polyurethane topcoats or ceramic nano-sealants—add critical barriers against moisture ingress and environmental pollutants. Regular inspections for microcracks, coupled with prompt repairs, further extend lifespan.

Pro tip: For coastal environments, opt for vinyl ester resins to combat salt spray corrosion.

Case studies, such as the Temple of Mnemon project in Miami, demonstrate how layered FRP panels with embedded drainage channels prevent water pooling—a common failure point. By merging rigorous engineering with artistic intent, designers can create installations that endure without compromising aesthetic impact.

FRP Composites in Outdoor Art

Fiberglass-reinforced polymer (https://en.artmovr.com/), FRP combines lightweight fiberglass with polymer resins, creating structures that withstand harsh weather without sacrificing design flexibility. This combination allows artists to craft intricate shapes—from flowing organic forms to geometric abstractions—while maintaining structural integrity in environments with high humidity, temperature fluctuations, or saltwater exposure.

A critical advantage of FRP lies in its resistance to corrosion, a common issue for metals in outdoor settings. The material’s non-porous surface prevents water absorption, reducing risks of cracking or warping over time. Additionally, FRP can be engineered with UV-resistant resins, minimizing color fading even under prolonged sunlight. For instance, large-scale public artworks in coastal areas often rely on FRP to avoid the accelerated degradation seen in untreated metals.

| Property | FRP Composites | Traditional Metals |

|---|---|---|

| Weight | Lightweight | Heavy |

| Corrosion Resistance | High | Moderate to Low |

| Maintenance Needs | Low | High |

| Design Flexibility | High | Limited |

While FRP offers clear functional benefits, its use in art also demands careful planning. Artists must balance resin-to-fiber ratios to ensure both strength and aesthetic precision. For example, thinner layers may allow finer details but require additional coatings for weatherproofing—a topic explored further in later sections. This interplay between material science and artistic vision defines modern outdoor installations, enabling creations that endure decades without compromising visual impact.

Choosing Durable FRP Materials

Selecting the right fiberglass-reinforced polymer (https://en.artmovr.com/) details, opt for fine-weave fiberglass mats that capture textures without compromising structural integrity.

Equally important are additives like UV inhibitors and fire retardants, which are blended into the resin matrix during production. For projects in humid or coastal environments, specify anti-hydrolysis agents to prevent moisture absorption—a common cause of delamination. Material thickness also plays a role: layered laminates with a gel coat barrier (minimum 15-20 mils) create a moisture-resistant shell. When sourcing FRP sheets or custom molds, verify compliance with ASTM C582 standards for outdoor polymer composites, ensuring consistent performance across temperature fluctuations. This careful selection process ensures the base materials withstand environmental stressors before protective coatings are even applied.

Structural Design for Weather Resistance

Effective structural design ensures fiberglass art installations withstand environmental stressors like wind, temperature fluctuations, and moisture. FRP composites inherently resist corrosion, but their geometry and reinforcement strategies determine long-term durability. For outdoor pieces, prioritize shapes that minimize water retention—sloped surfaces, rounded edges, and open frameworks reduce pooling and ice formation. Internal reinforcement with materials like carbon fiber or stainless steel mesh adds tensile strength, preventing cracks caused by thermal expansion. Joints and connection points require special attention; overlapping layers and flexible adhesives accommodate movement without compromising integrity.

For dynamic installations, such as kinetic sculpture, balance lightweight construction with aerodynamic stability. Finite element analysis (FEA) can simulate stress distribution under wind loads, guiding adjustments to wall thickness or support placement. Pairing these engineering principles with artistic vision ensures designs remain visually striking while meeting technical demands. This approach bridges material selection (discussed earlier) and protective coatings (explored next), forming a cohesive strategy for outdoor resilience.

Protective Coatings for Longevity

The application of specialized protective coatings is critical to extending the lifespan of fiberglass art installations exposed to harsh weather. UV-resistant polyurethane topcoats shield surfaces from solar degradation, preventing color fading and surface cracking, while epoxy primers create a corrosion-resistant barrier against moisture infiltration. For coastal or high-humidity environments, marine-grade sealants with anti-oxidation additives combat saltwater corrosion and fungal growth.

Complementing structural design choices, coatings must address thermal expansion by maintaining flexibility across temperature fluctuations. Modern hybrid formulations, such as silicone-acrylic blends, balance adhesion and elasticity to withstand wind-driven debris and freeze-thaw cycles. Proper application—including multi-layer spraying and edge sealing—ensures uniform coverage, particularly in complex geometries common in Fiberglass sculpture.

Regular inspections should focus on abrasion-prone areas, as even minor scratches can compromise weatherproofing. By integrating these coatings during fabrication, artists and engineers collaboratively preserve both aesthetic intent and material integrity, bridging the gap between creative vision and environmental resilience.

Maintaining Fiberglass Art Installations

While proper design and protective coatings form the foundation of weather-resistant fiberglass art, routine maintenance ensures long-term durability. Begin with regular inspections—ideally biannually—to identify surface cracks, discoloration, or coating degradation. Use mild, pH-neutral cleaners to remove dirt and organic growth, avoiding abrasive tools that could scratch the gel coat. For intricate elements common in cartoon sculptures, soft brushes or low-pressure water rinses prevent detail erosion. Address minor damage promptly: sand affected areas lightly, apply UV-resistant resin patches, and re-seal with compatible topcoats.

Environmental factors like prolonged UV exposure or saltwater proximity may require more frequent recoating cycles. Track temperature fluctuations in your region, as thermal expansion can stress joints over time. Documentation of maintenance activities helps predict wear patterns, allowing proactive repairs. By integrating these practices, installations retain structural integrity and visual appeal, bridging the gap between artistic vision and material resilience.

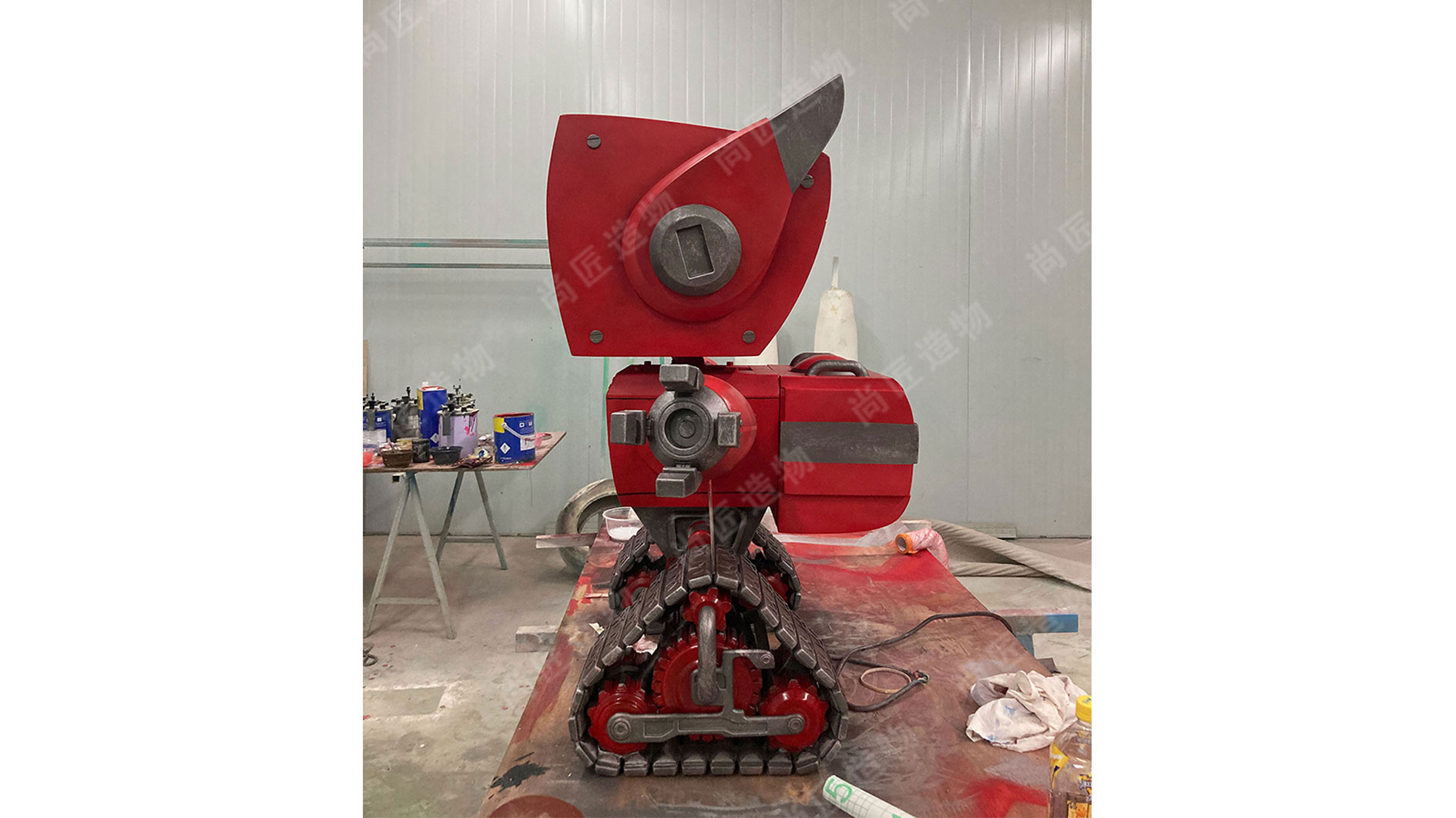

Case Study: Temple of Mnemon Project

The Temple of Mnemon Project, a public art installation in coastal Norway, illustrates how fiberglass-reinforced polymer (FRP) composites can withstand extreme weather while preserving artistic intent. Located in a region with heavy rainfall, salt spray, and subzero winters, the structure’s design prioritized seamless integration of durability and symbolism. Architects selected isophthalic polyester resin for its moisture resistance, paired with a multi-layer gelcoat system to prevent UV degradation. The team avoided flat surfaces prone to water pooling, instead using curved geometries inspired by Norse mythology to naturally shed precipitation.

Structural reinforcement included embedded stainless steel supports within critical load-bearing sections, a technique that balances weight reduction with storm resilience. For surface protection, a hybrid coating of polyurethane and anti-graffiti sealant was applied, ensuring both color retention and ease of maintenance. Notably, the installation’s central IP character sculpture required custom mold adjustments to prevent thermal expansion cracks in winter—a challenge resolved through iterative prototyping. Post-installation inspections at 6-month intervals have shown no warping or delamination after three years, validating the project’s weather-resistant framework. This approach underscores the importance of adapting material science and structural logic to environmental demands without compromising artistic vision.

Balancing Aesthetics and Durability

Creating outdoor fiberglass art that withstands harsh weather without sacrificing visual appeal requires deliberate planning. While FRP composites offer flexibility in shaping intricate designs, their long-term performance depends on integrating artistic vision with material science. Start by selecting resin matrices with UV inhibitors to prevent yellowing, ensuring colors remain vibrant under sunlight. Textured surfaces or geometric patterns can mask minor weathering effects while adding visual depth.

Structural reinforcement should complement the artwork’s form—strategically placed ribs or honeycomb cores strengthen thin sections without disrupting flowing lines. Transparent gel coats preserve surface details while acting as a moisture barrier, but matte or metallic finishes may better hide environmental wear. Consider how light interacts with the piece: angled surfaces reduce water pooling, and open designs minimize wind resistance. Collaboration between artists and engineers during prototyping ensures technical solutions enhance, rather than compromise, the intended aesthetic. This synergy allows installations like the Temple of Mnemon to retain their narrative power while enduring decades of exposure.

Avoiding Common FRP Installation Errors

While selecting durable materials and protective coatings is critical, installation mistakes can compromise even the most weather-resistant fiberglass art. One frequent error involves improper surface preparation before applying coatings. Dust, moisture, or uneven textures left on FRP surfaces reduce adhesion, leading to premature peeling. Another oversight is neglecting thermal expansion gaps—fiberglass expands and contracts with temperature shifts, and rigid installations risk cracks or warping over time.

Incorrect resin-to-catalyst ratios during assembly also weaken structural integrity. Too much catalyst accelerates curing but creates brittle sections, while insufficient catalyst leaves the material under-hardened. Additionally, rushed curing in humid or cold environments often results in incomplete polymerization, reducing UV and moisture resistance. To avoid these pitfalls, always follow manufacturer guidelines for mixing ratios, environmental conditions, and curing timelines.

Finally, poorly sealed joints or mounting points invite water infiltration, accelerating corrosion in metal supports. Use marine-grade sealants and stainless steel hardware to maintain durability. By addressing these installation nuances, artists and engineers ensure outdoor fiberglass installations withstand decades of exposure without sacrificing visual impact.

Conclusion

Designing weather-resistant fiberglass art installations demands a systematic approach that integrates material science, engineering principles, and artistic vision. By prioritizing durable FRP composites, optimizing structural designs to withstand environmental stressors, and applying advanced protective coatings, artists and fabricators can ensure installations retain their visual and structural integrity for decades. Regular maintenance, informed by site-specific climate conditions, further extends longevity while preserving aesthetic intent. The Temple of Mnemon case study illustrates how rigorous planning and collaboration between artists and engineers yield installations that harmonize creativity with resilience. While challenges like thermal expansion or UV degradation require careful mitigation, advancements in fiberglass technology continue to expand possibilities for outdoor art. Ultimately, the success of such projects hinges on balancing innovation with proven durability strategies, ensuring artworks not only captivate audiences but also endure as lasting cultural landmarks.

FAQs

What makes fiberglass-reinforced polymer (FRP) suitable for outdoor art installations?

FRP composites combine fiberglass strands with resin matrices, creating materials that resist moisture, UV radiation, and temperature fluctuations. This inherent durability minimizes warping, cracking, and corrosion in harsh weather conditions.

How often should protective coatings be reapplied to FRP art?

Most high-performance polyurethane or epoxy coatings last 5–8 years, depending on climate severity. Annual inspections help identify early signs of fading or surface erosion, allowing timely recoating.

Can FRP installations withstand extreme weather like hurricanes or heavy snow?

Properly engineered FRP structures distribute weight evenly and flex under stress, reducing fracture risks. Anchoring systems and aerodynamic designs further enhance resilience against high winds or snow loads.

Are there environmental concerns with using fiberglass composites?

Modern FRP formulations often incorporate recycled materials and low-VOC resins. Proper sealing prevents microplastic shedding, while UV-resistant coatings reduce chemical degradation over time.

What maintenance steps extend the lifespan of outdoor fiberglass art?

Routine cleaning with mild detergents removes debris and pollutants. Inspect joints and coatings biannually, and address minor cracks promptly using compatible patching compounds to prevent water infiltration.

How does FRP compare to traditional metals like bronze for public art?

FRP offers comparable strength at 30–50% lighter weight, reducing foundation costs. Unlike metals, it doesn’t require anti-rust treatments, though initial material costs may be higher depending on design complexity.

ch

ch English

English