Key Takeaways

Integrating motors into kinetic metal art requires balancing mechanical precision with artistic vision. First, consider the motor’s visibility: concealed drive systems, such as recessed mounts or hollow structural cavities, maintain visual focus on the sculpture’s form while enabling motion. For sculptures inspired by vintage designs, clockwork mechanisms paired with modern motors offer a blend of analog charm and reliable automation.

Tip: When selecting motors, prioritize brushless DC models for reduced wear and quieter operation—critical for installations in public spaces.

Adjustable timing controls, like programmable microcontrollers or variable resistors, allow artists to fine-tune motion patterns without altering physical components. Durability is non-negotiable; opt for stainless steel brackets or vibration-dampening mounts to protect motors from environmental stressors. For projects aiming to evoke Realistic sculpture aesthetics, seamless motor integration ensures mechanical elements complement—not compete with—the artwork’s narrative.

"A motor’s lifespan hinges on alignment," notes industrial sculptor Mara Voss. "Even a 1mm offset can multiply friction over time."

Lastly, plan for maintenance access. Removable panels or modular motor housings simplify inspections, ensuring kinetic sculptures remain in motion for decades.

Hidden Drive System Designs for Metal Art

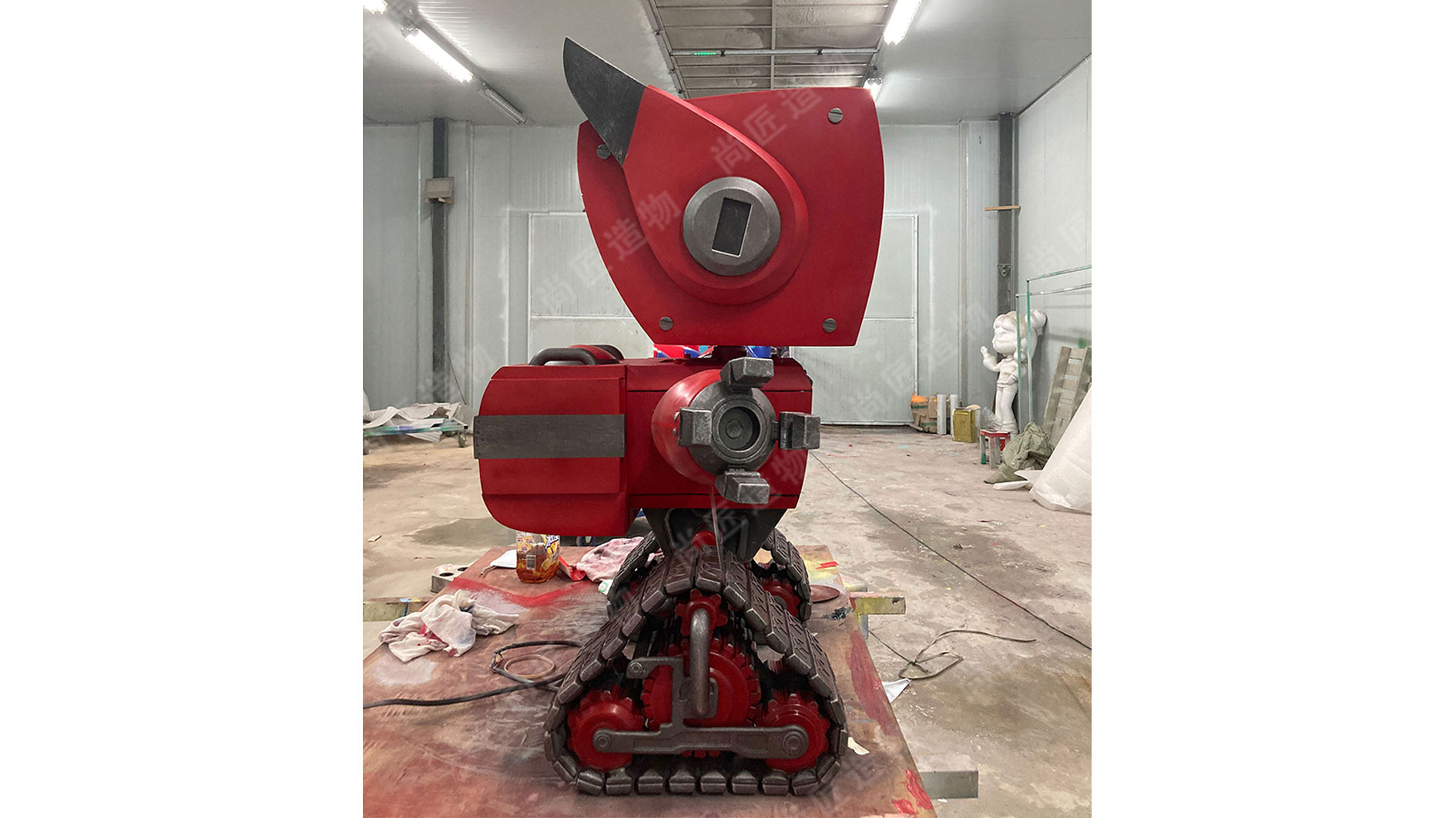

Concealing mechanical components without compromising motion is central to kinetic metal art. Hidden drive systems often involve embedding motors within hollow cavities or structural voids in the sculpture’s framework. For example, cylindrical motors can be housed inside geometrically aligned tubing, while flat stepper motors might nest within layered metal plates. One effective approach uses concentric shafts or false panels to mask rotational mechanisms, ensuring moving elements appear self-propelled.

Advanced systems integrate microcontrollers and wireless power solutions to eliminate visible wiring. For instance, induction coils hidden beneath polished surfaces can transmit energy to internal motors, as seen in some IP character sculpture installations. Engineers recommend prioritizing corrosion-resistant enclosures, especially for outdoor pieces, using silicone seals or powder-coated aluminum housings. Alignment with the sculpture’s center of gravity prevents uneven wear, while vibration-dampening mounts reduce noise from concealed motors. These techniques maintain visual purity while enabling seamless kinetic interaction.

Clockwork Mechanisms in Kinetic Sculptures

Clockwork mechanisms offer a timeless approach to powering kinetic metal sculptures, combining mechanical precision with artistic expression. These systems rely on coiled springs or weighted drives to store energy, which is released through interconnected gears and escapements. Unlike motorized installations, clockwork designs create cyclical motion patterns governed by gear ratios and tension adjustments, often evoking the charm of 18th-century automata.

For metal artists, integrating clockwork requires balancing structural integrity with kinetic efficiency. Stainless steel or brass gears (https://en.artmovr.com/) framework can sometimes complement metal clockwork components by reducing overall weight.

| Component | Function | Material Considerations |

|---|---|---|

| Mainspring | Energy storage | High-carbon steel (0.6–0.8 mm thickness) |

| Gear Train | Motion transmission | Brass (for low friction) or stainless steel |

| Escapement | Regulate energy release | Titanium alloys (wear resistance) |

While clockwork systems eliminate electrical dependencies, they demand meticulous calibration. For instance, adjusting the pallet fork’s engagement depth by 0.1–0.3 mm can alter motion duration by 15–30%. Modern adaptations often hybridize traditional clockwork with programmable triggers, allowing synchronized activation of multiple sculpture elements. This fusion maintains the vintage aesthetic while enabling predictable performance in outdoor environments.

Adjustable Timing Control Methods for Motion

Precision timing lies at the heart of kinetic sculptures, where motion patterns must align with artistic intent. Three primary approaches enable adjustable control: pulse-width modulation (PWM) circuits, programmable microcontrollers, and mechanical escapement adjustments. PWM systems regulate motor speed through rapid power switching, allowing artists to fine-tune movement speed without altering voltage. For example, a 12V motor paired with a 50% PWM cycle mimics 6V operation while maintaining torque efficiency.

Microcontrollers like Arduino or Raspberry Pi offer granular timing customization through code-based intervals, enabling complex sequences such as staggered rotations or rhythmic pauses. These systems often integrate light or sound sensors to synchronize motion with environmental stimuli. Mechanical alternatives include adjustable gear ratios in kinetic sculpture clockwork assemblies, where repositioning linkage pins alters cycle durations.

Hybrid solutions combine digital precision with tactile adjustability—knobs or sliders connected to potentiometers let viewers interactively modify motion timing. Durability remains critical; sealed rotary encoders or optical sensors prevent dust interference in outdoor installations. Artists often layer timing methods, using microcontrollers for primary rhythms and mechanical governors as fail-safes, ensuring consistent operation even during power fluctuations.

Durable Motor Mounting Solutions for Sculptures

Securing motors within kinetic metal art requires balancing structural integrity with aesthetic subtlety. For outdoor installations, corrosion-resistant materials like stainless steel or powder-coated aluminum provide lasting support while resisting weathering. Vibration-dampening mounts, such as rubber isolators or silicone pads, reduce wear caused by repetitive motion, particularly in sculptures with rotating or oscillating components.

Embedding motors directly into welded frames ensures stability, though access panels may be added for maintenance. For smaller pieces, stainless steel sculpture bases often integrate threaded inserts or epoxy-sealed mounting plates to anchor compact DC motors without visible hardware. Adjustable tension clamps allow precise alignment of drive shafts, critical for synchronizing multi-motor systems. Weatherproof enclosures rated IP65 or higher protect internal mechanisms in exposed environments, while thermal-resistant gaskets prevent heat transfer from motors to surrounding metal surfaces. These solutions prioritize longevity without compromising the artwork’s fluid motion or visual coherence.

Choosing Motors for Long-Lasting Kinetic Art

Selecting the right motor for kinetic metal sculptures requires balancing technical precision with artistic intent. For sustained performance, prioritize motors with sealed housings to resist dust and moisture—critical for outdoor installations. Low-voltage DC motors, such as 12V or 24V models, offer energy efficiency while maintaining sufficient torque for rotational or oscillating movements. Brushless designs reduce wear over time, minimizing maintenance needs. Gear motors with adjustable RPM (rotations per minute) allow artists to fine-tune motion speed without straining components.

When integrating motors into structural frameworks, consider weight distribution. Overloading a motor accelerates burnout; calculate load capacity using manufacturer specifications, factoring in metal density and sculpture dimensions. For example, a cartoon sculpture requiring subtle motion might pair a compact 5W motor with a planetary gearbox for smooth, quiet operation. Temperature tolerance is equally vital—opt for motors rated for at least -20°C to 50°C to withstand seasonal shifts. Pairing these choices with corrosion-resistant mounting brackets ensures both stability and longevity, aligning mechanical reliability with the sculpture’s aesthetic lifespan.

Perpetual Motion Art Techniques with Clockwork

Clockwork mechanisms offer a timeless approach to creating the illusion of perpetual motion in kinetic metal sculptures. Unlike motorized systems, clockwork relies on carefully calibrated gears, springs, and escapements to generate rhythmic, self-sustaining movement. Artists often combine these components with weighted pendulums or flywheels to extend motion duration, mimicking infinite cycles through mechanical energy storage. Precision is critical—gears must align flawlessly to minimize friction, while spring tension requires calibration to balance force distribution without overloading the system.

For seamless integration, clockwork elements are often concealed within hollow metal frameworks or disguised as decorative features, such as spiral accents or layered patterns. Stainless steel and brass are preferred materials due to their corrosion resistance and ability to withstand repetitive stress. To enhance longevity, artists incorporate adjustable timing regulators—like screw-modified pendulum lengths or variable flywheel weights—to fine-tune motion patterns. This hybrid of traditional horology and modern metallurgy allows sculptures to operate for hours or days between manual rewinding, bridging the gap between mechanical authenticity and artistic practicality. When paired with occasional lubrication and tension checks, clockwork systems provide a low-tech yet elegant solution for kinetic art that prioritizes tactile interaction over automated control.

Aesthetic Motor Integration in Metal Designs

Integrating motors into kinetic metal sculptures requires balancing mechanical functionality with visual harmony. Rather than treating motors as purely utilitarian components, artists often embed them within structural elements to maintain the sculpture’s aesthetic integrity. For example, drive systems can be concealed inside hollow chambers or masked by overlapping metal plates that echo the artwork’s geometric or organic forms. Custom motor housings—crafted from materials like brushed steel or oxidized copper—blend seamlessly with the sculpture’s surface texture, ensuring the machinery complements rather than disrupts the design.

Transitioning from hidden placements to intentional visual integration, some kinetic pieces highlight motors as sculptural features. This approach works particularly well in industrial-themed art, where polished gears or exposed belt drives become focal points. For softer aesthetics, motors can be nested within abstract shapes or coated with patina to mimic aged metal details. Adjustable mounting brackets allow repositioning during the design phase, enabling artists to test how motor placement affects both motion dynamics and visual balance. By aligning mechanical elements with the sculpture’s narrative—whether futuristic, rustic, or minimalist—the motor becomes an extension of the artwork’s storytelling.

Kinetic Sculpture Maintenance and Motor Care

Regular maintenance ensures kinetic sculptures retain their functionality and visual appeal over time. Start by inspecting moving parts monthly for signs of wear, such as frayed wires or loose fasteners. Dust and debris accumulation, particularly near motor housings, can interfere with motion—use compressed air or soft brushes for cleaning. Lubricate gears and bearings with lightweight, non-corrosive oils to minimize friction, but avoid over-application to prevent residue buildup.

Motor care requires attention to electrical components. Check connections for corrosion, especially in outdoor installations exposed to moisture. Waterproof enclosures or silicone sealants can protect sensitive parts. Test motor speeds periodically using adjustable timing controls to ensure consistency, as fluctuations may indicate worn brushes or voltage irregularities. For sculptures using clockwork mechanisms, manually wind components to assess tension and alignment.

Environmental factors play a role—position artworks away from extreme temperatures or humidity, which accelerate metal fatigue and motor degradation. Document maintenance dates and observations to identify patterns, such as seasonal wear. By integrating these practices, artists extend the lifespan of both mechanical and artistic elements, preserving the sculpture’s kinetic integrity while reducing long-term repair costs.

Conclusion

Integrating motors into kinetic metal sculptures requires balancing mechanical precision with artistic vision. While motors provide dynamic movement, their successful incorporation hinges on thoughtful design choices that prioritize both function and form. Selecting appropriate drive systems—whether hidden mechanisms or visible clockwork elements—determines how seamlessly motion blends with the sculpture’s aesthetic. Durability remains critical; robust mounting solutions and weather-resistant materials ensure longevity, especially for outdoor installations.

Adjustable timing controls allow artists to refine motion patterns, creating rhythms that enhance the viewer’s experience. Meanwhile, low-maintenance motor choices reduce operational interruptions, preserving the artwork’s continuity. By marrying technical reliability with creative expression, artists can craft pieces that transcend static forms, inviting audiences to engage with art in motion.

Ultimately, the fusion of motors and metalwork opens new possibilities for kinetic art. Through careful planning and innovative engineering, sculptures gain the ability to evolve over time, offering perpetual fascination while standing as testaments to the synergy between human ingenuity and mechanical innovation.

Frequently Asked Questions

What’s the best way to hide motors in kinetic metal sculptures?

Embedding motors within hollow structural elements, such as bases or internal frames, keeps them discreet. Decorative covers or textured metal plates can further camouflage mechanical components while maintaining accessibility for maintenance.

Can clockwork mechanisms replace electric motors entirely?

While clockwork systems offer vintage appeal and avoid wiring, they require frequent winding and precise calibration. Hybrid designs combining clockwork with low-power motors for periodic rewinding balance aesthetics and practicality.

How do I prevent motor vibrations from destabilizing sculptures?

Rubberized mounts or silicone dampeners absorb vibrations. For heavier motors, reinforce mounting points with welded brackets or threaded bolts to distribute kinetic forces evenly across the sculpture’s framework.

What motor specifications suit long-lasting kinetic art?

Opt for brushless DC motors with sealed bearings, as they minimize friction and dust ingress. Motors rated for continuous duty cycles (≥10,000 hours) and low RPM (5-60) ensure smooth, enduring motion without overheating.

Are adjustable timing controls complicated to install?

Basic analog timers or microcontrollers like Arduino can regulate motion intervals. Pre-wired modular kits simplify integration, allowing artists to adjust speed or pause durations via dials or smartphone apps.

How often should kinetic sculptures undergo maintenance?

Inspect motor mounts and lubrication every 3-6 months, depending on exposure to dust or moisture. For outdoor installations, apply corrosion-resistant coatings and check electrical connections seasonally.

Can perpetual motion concepts work in real-world sculptures?

True perpetual motion is impossible, but solar-powered motors or energy-efficient designs with flywheels can simulate near-continuous movement for extended periods, reducing reliance on manual intervention.

ch

ch English

English