Key Takeaways

Integrating kinetic elements into polished steel statues transforms static artworks into dynamic installations. Wind-powered movement systems based on Whitaker's techniques enable fluid motion while preserving structural integrity. These methods prioritize weather-resistant engineering, using marine-grade stainless steel bearings and aerodynamic counterbalances to ensure decades of operation with minimal upkeep. The seamless fusion of motion and metal requires precise weight distribution calculations, as improperly balanced components accelerate wear.

"Kinetic steel art must achieve equilibrium between artistic vision and mechanical reality—every pivot point must account for wind loads and metal fatigue," notes a conservator from the International Sculpture Center.

Transformation involves three critical phases:

- Structural adaptation - Reinforcing core frameworks

- Motion integration - Installing low-friction pivot systems

- Surface preservation - Applying protective clearcoats

| Feature | Static Sculpture | Kinetic Conversion |

|---|---|---|

| Maintenance Interval | 2-3 years | 5-7 years |

| Wind Tolerance | Moderate | High (70+ mph) |

| Interactive Potential | Limited | High |

The conversion process enhances traditional Realistic sculpture by introducing environmental responsiveness, where breezes activate graceful movements without compromising the polished finish. Proper engineering prevents stress fractures at joint locations, a common failure point in early kinetic experiments. For optimal results, install kinetic elements during initial fabrication rather than retrofitting existing pieces.

Kinetic Techniques for Steel Art Transformation

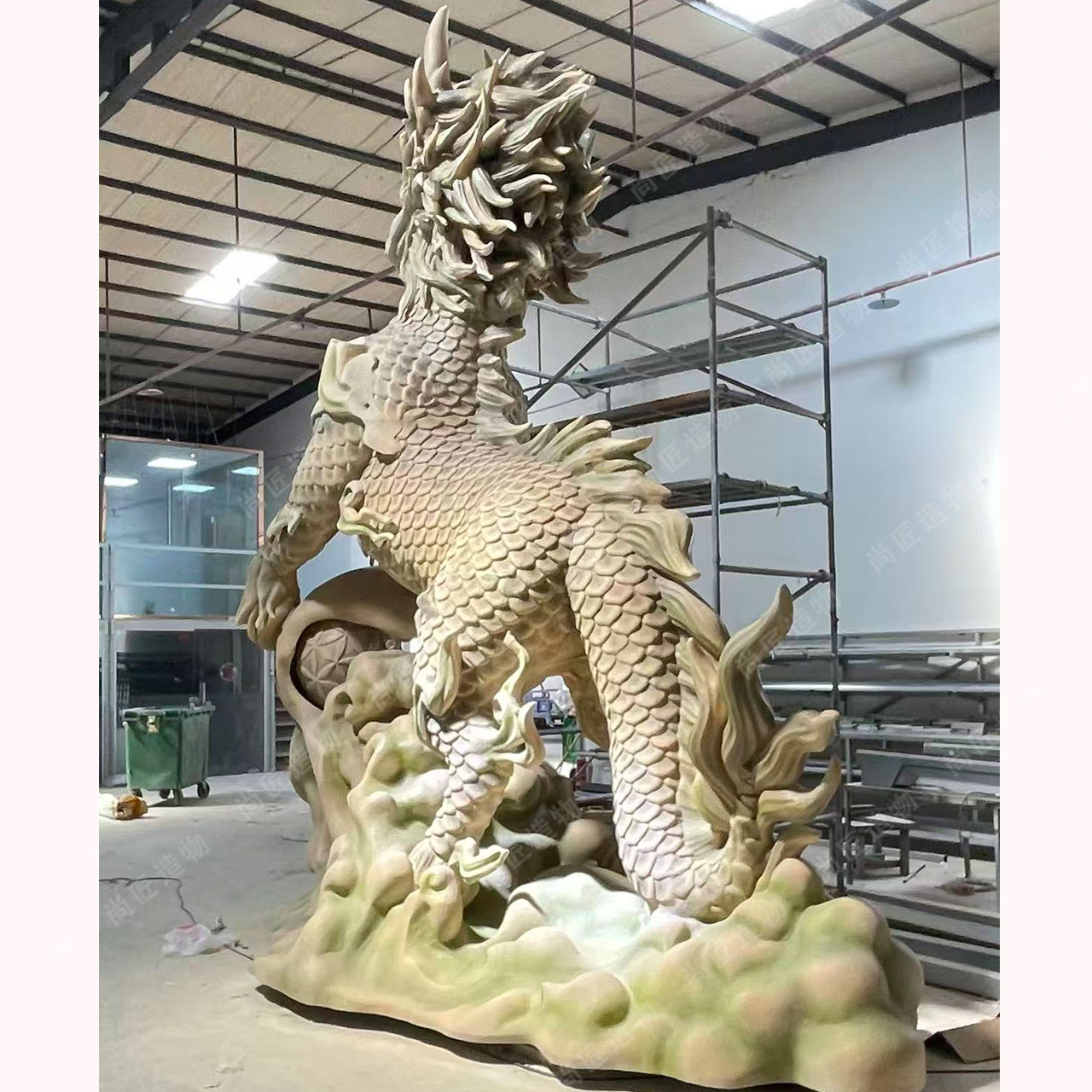

Integrating movement into polished steel statues requires specialized kinetic techniques that respect the material's properties while enabling fluid motion. This transformation involves carefully engineering internal or attached mechanisms designed to respond reliably to environmental forces like wind. The design phase is critical, demanding precise calculation of weight distribution, pivot points, and bearing tolerances to ensure smooth, silent operation without compromising the structural integrity of the steel. Selecting the right type of motion—whether rotation, oscillation, or subtle shifting—depends heavily on the sculpture's form and the artist's intended interaction with its surroundings. Successfully merging mechanics with aesthetics means these components must be virtually invisible or become an intentional part of the visual design. This foundational engineering ensures the transition from static metalwork to enduring kinetic art is seamless, paving the way for utilizing specific forces like wind to animate the piece. Specialized components, such as those developed for intricate IP character sculpture, often inform the precision needed for reliable, long-term movement in demanding outdoor settings.

Wind-Powered Movement in Metal Sculptures

Wind offers a naturally sustainable energy source for introducing movement into polished steel sculptures. Harnessing this power effectively requires careful consideration of the sculpture's form and balance. Key to successful integration is designing components that react predictably to varying wind speeds. These moving parts, often blades, vanes, or carefully balanced abstract shapes, must be precisely engineered. Their pivot points need low friction bearings and robust weather seals to ensure smooth, silent operation over decades. The highly polished steel surface itself plays a role; its smoothness minimizes wind resistance and helps prevent debris accumulation that could impede motion.

Achieving elegant, reliable rotation or oscillation depends heavily on aerodynamic principles applied to the sculpture's specific geometry. Placement is also critical; sculptures intended for wind activation should be situated where prevailing breezes are consistent and unobstructed. Understanding these factors allows artists to transform static polished forms into captivating, ever-changing kinetic sculpture. This sets the foundation for exploring specific methods to ensure this movement lasts, requiring durable engineering solutions.

Whitaker Methods for Lasting Steel Kinetics

Building upon wind-powered movement concepts, Whitaker's techniques provide a systematic approach for integrating enduring kinetic mechanisms into polished steel statues. His methodology centers on precision-engineered internal pivot points and balanced weight distribution, ensuring smooth, silent motion even in variable wind conditions. Crucially, these moving components are constructed using marine-grade alloys and specialized low-friction bearings, specifically chosen for their compatibility with polished surfaces and extreme environmental resilience. This focus on material compatibility prevents galvanic corrosion where dissimilar metals interact, a common failure point in kinetic art. Furthermore, Whitaker advocates for sealed, maintenance-free bearing systems within the sculpture's structure, drastically reducing long-term upkeep needs. His documented standards for salt-spray resistance and cyclical stress testing guarantee that the dynamic elements within the stainless steel sculpture maintain functional integrity for decades. This engineering rigor allows the kinetic aspect to become a permanent, reliable feature of the artwork, not merely a temporary addition. The result transforms static polished forms into sculptures possessing both visual brilliance and perpetual, graceful movement.

Engineering Weather-Resistant Kinetic Statues

Designing kinetic sculptures for permanent outdoor installation demands deliberate material science and structural engineering. Stainless steel alloys like 316L provide foundational corrosion resistance, particularly in coastal or high-humidity environments. Critical joints incorporate marine-grade bronze bearings with triple-sealed housings to block moisture ingress while allowing fluid movement. Surface treatments begin with electropolishing to eliminate microscopic pores where corrosion could initiate, followed by ceramic-based clear coats that repel UV damage without dulling the metallic luster. Drainage channels integrated into rotating components prevent water pooling, while wind-load calculations inform counterbalance systems that prevent stress fractures during storms. These principles draw inspiration from protective techniques used in fiberglass sculpture, adapted for metal's thermal expansion properties. By preempting environmental degradation pathways, kinetic mechanisms maintain operational integrity across seasonal extremes, reducing long-term maintenance to simple annual inspections.

Seamless Motion Integration in Steel Art

Achieving fluid movement within polished steel statues requires meticulous engineering to preserve their aesthetic integrity. The core challenge lies in concealing functional mechanisms beneath the flawless metal surface. Precision-engineered pivot points and bearings, crafted from specialized, corrosion-resistant alloys, are embedded deep within the sculpture's structure. These critical components, pioneered by innovators like Whitaker, are designed to operate smoothly and silently, minimizing friction even after years of exposure. The integration demands exact alignment; any slight deviation would cause binding or unwanted noise, disrupting the intended grace. This contrasts sharply with more overtly mechanical styles, such as playful cartoon sculpture, where joints might be part of the visual appeal. Here, every moving part must function flawlessly while remaining entirely invisible, ensuring the polished steel exterior appears as a single, undisturbed form that moves as if by magic. The artistry is in making complex mechanics disappear, leaving only effortless motion.

Low Maintenance Kinetic Steel Sculptures

Building upon durable engineering foundations, kinetic steel sculptures achieve remarkable longevity with minimal upkeep demands. The combination of polished stainless steel's inherent corrosion resistance and Whitaker's precision bearing systems creates self-sustaining movement mechanisms. Unlike traditional sculptures requiring frequent polishing or lubrication, these installations utilize sealed rotational joints that repel environmental contaminants. Their balanced wind-responsive elements operate smoothly without external power sources or complex mechanical adjustments. Rainwater naturally cleans the polished surfaces while specialized marine-grade alloys prevent salt damage in coastal installations. This maintenance efficiency makes kinetic steel sculptures particularly suitable for public spaces where accessibility for upkeep is limited. The design philosophy prioritizes decades of uninterrupted motion through intelligent material selection and friction-reducing engineering.

Polished Steel to Dynamic Art Conversion

Transforming polished steel statues into dynamic artworks requires careful engineering to preserve structural integrity while introducing movement. The process begins with precise analysis of the existing sculpture's weight distribution and balance points. Engineers then design internal or external kinetic mechanisms that complement the artwork's form without compromising its aesthetic value. These systems often incorporate specialized bearings and pivot points, allowing sections to move smoothly in response to wind currents or other environmental forces. Crucially, the conversion maintains the signature polished finish, demanding meticulous attention to how moving parts interact at joints to prevent scratching or premature wear. Material selection is paramount; components must match the base metal's expansion rates and corrosion resistance to ensure seamless operation across temperature variations. This integration converts static elegance into responsive motion, where the play of light on polished surfaces gains an added dimension as forms shift and turn. The transition demands expertise in both metallurgy and kinetics, ensuring the sculpture's new dynamic nature appears organic rather than added-on, preserving the original artistic intent while unlocking new expressive potential through controlled, enduring motion.

Durability Engineering for Moving Metalwork

Beyond the initial motion design, ensuring the long-term survival of kinetic elements within polished steel statues demands rigorous engineering focused on durability. The constant movement introduces unique stresses not present in static works, making material selection and protection paramount. Engineers prioritize corrosion-resistant alloys, often specifying marine-grade stainless steel for critical moving parts exposed to weather. Bearings and pivots, vital for smooth motion, are meticulously sealed within weatherproof casings to prevent ingress of water, dust, and abrasive particles like sand, which can cause rapid wear and seizure. Furthermore, the structural design meticulously accounts for dynamic loads and potential metal fatigue over thousands, even millions, of motion cycles. Protective coatings compatible with the polished finish are applied to shield surfaces without compromising reflectivity, while drainage paths prevent water pooling. This comprehensive approach ensures the kinetic sculpture functions reliably for decades, minimizing maintenance needs and preserving both its aesthetic appeal and mechanical integrity against environmental challenges. Testing often involves accelerated weathering and salt spray exposure (like ASTM G85) to validate material choices and protective measures under simulated harsh conditions.

Conclusion

As demonstrated, incorporating kinetic elements into polished steel statues represents a transformative approach to metal artistry. By applying Whitaker's proven methodologies, artists can reliably convert static forms into dynamic sculptures powered by natural wind energy. This integration process prioritizes both aesthetic continuity and functional resilience, ensuring motion complements rather than compromises the polished steel's visual impact. Crucially, the engineering principles discussed—focusing on corrosion resistance, balanced movement mechanics, and robust structural design—directly contribute to exceptional longevity. The result is an enduring artwork that maintains its kinetic functionality across decades with minimal upkeep requirements. This practical fusion of artistic vision with durable kinetic engineering ultimately creates sculptures that engage viewers through movement while preserving the timeless elegance of polished metal, securing their legacy for future generations.

Frequently Asked Questions

How often do kinetic steel sculptures require maintenance?

Properly engineered pieces using Whitaker methods typically need only annual inspections. Weather-resistant bearings and stainless steel components minimize upkeep.

Will wind movement damage polished steel surfaces over time?

Advanced joint designs prevent metal-on-metal contact. Sealed rotational mechanisms and marine-grade polishing techniques maintain surface integrity through decades of motion.

What wind speeds activate these sculptures effectively?

Most installations begin moving at 5-8 mph breezes. Counterweight calibration ensures responsive motion without instability during stronger gusts.

Can existing polished steel statues be converted to kinetic art?

Structural analysis determines feasibility. Typically, only sculptures with sufficient base weight and balanced mass distribution qualify for safe retrofitting.

How are bearings protected from weather elements?

Stainless steel housings with triple-labyrinth seals exclude moisture and debris. This engineering approach aligns with permanent outdoor installation standards.

ch

ch English

English