Key Takeaways

Successfully transforming merchandise designs into permanent stainless steel sculptures requires attention to several interconnected phases. The journey begins with effectively translating two-dimensional graphics into viable three-dimensional forms, demanding careful consideration of volume, negative space, and structural logic inherent in the original design. This adaptation process then directly influences the selection of appropriate stainless steel fabrication methods, such as precision cutting, welding, and forming techniques, to accurately realize the sculptural vision. Crucially, structural engineering principles must be integrated early to ensure the artwork's stability and longevity in an outdoor public setting. Material choice, specifically stainless steel, inherently supports durability, but surface finishing techniques further enhance both aesthetics and resistance to environmental factors. Finally, thoughtful site-specific placement is essential, considering visibility, public interaction, and the surrounding environment to maximize the sculpture's impact and integration within the public realm. Each stage informs the next, creating a cohesive process from concept to enduring installation.

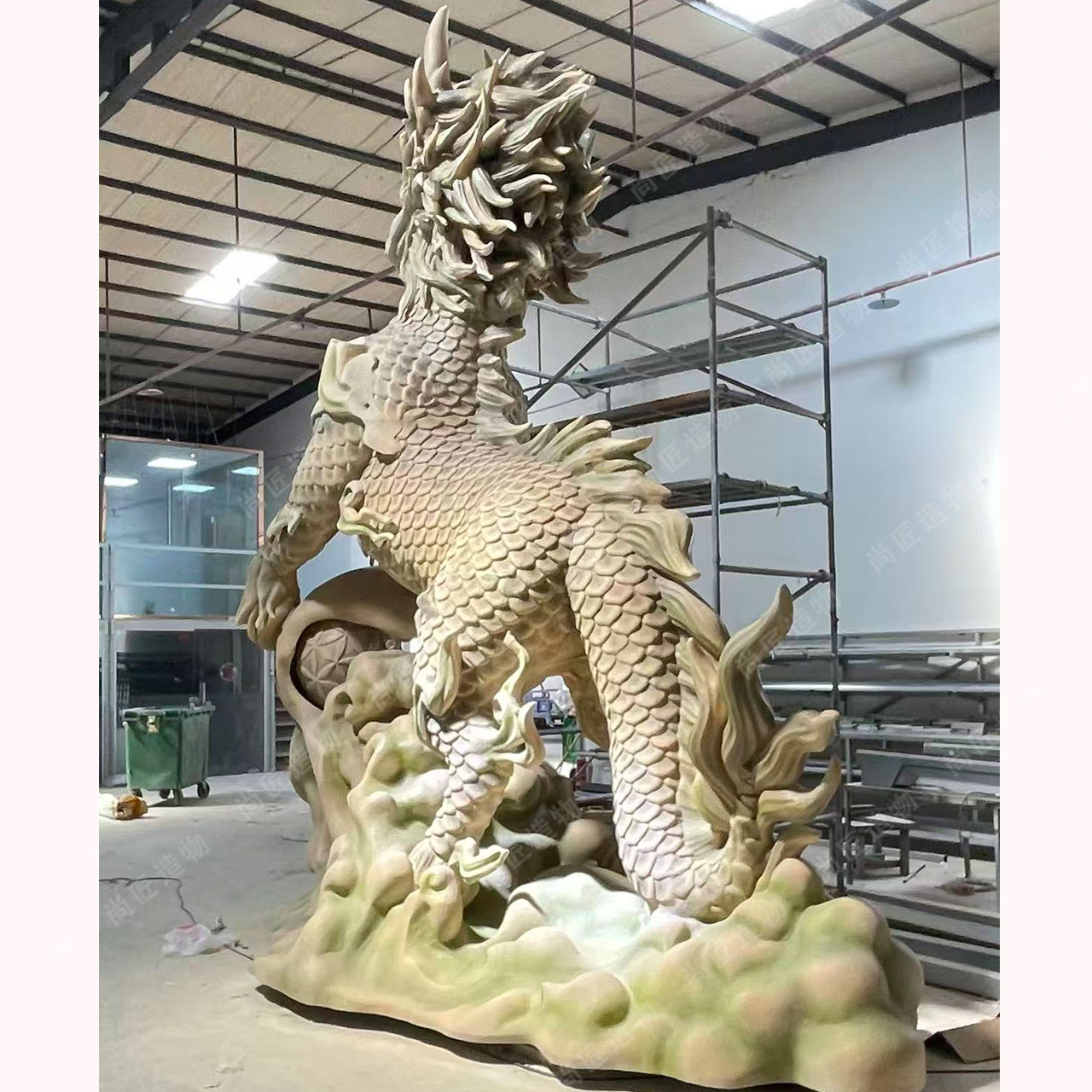

From Merchandise to Metal Concepts

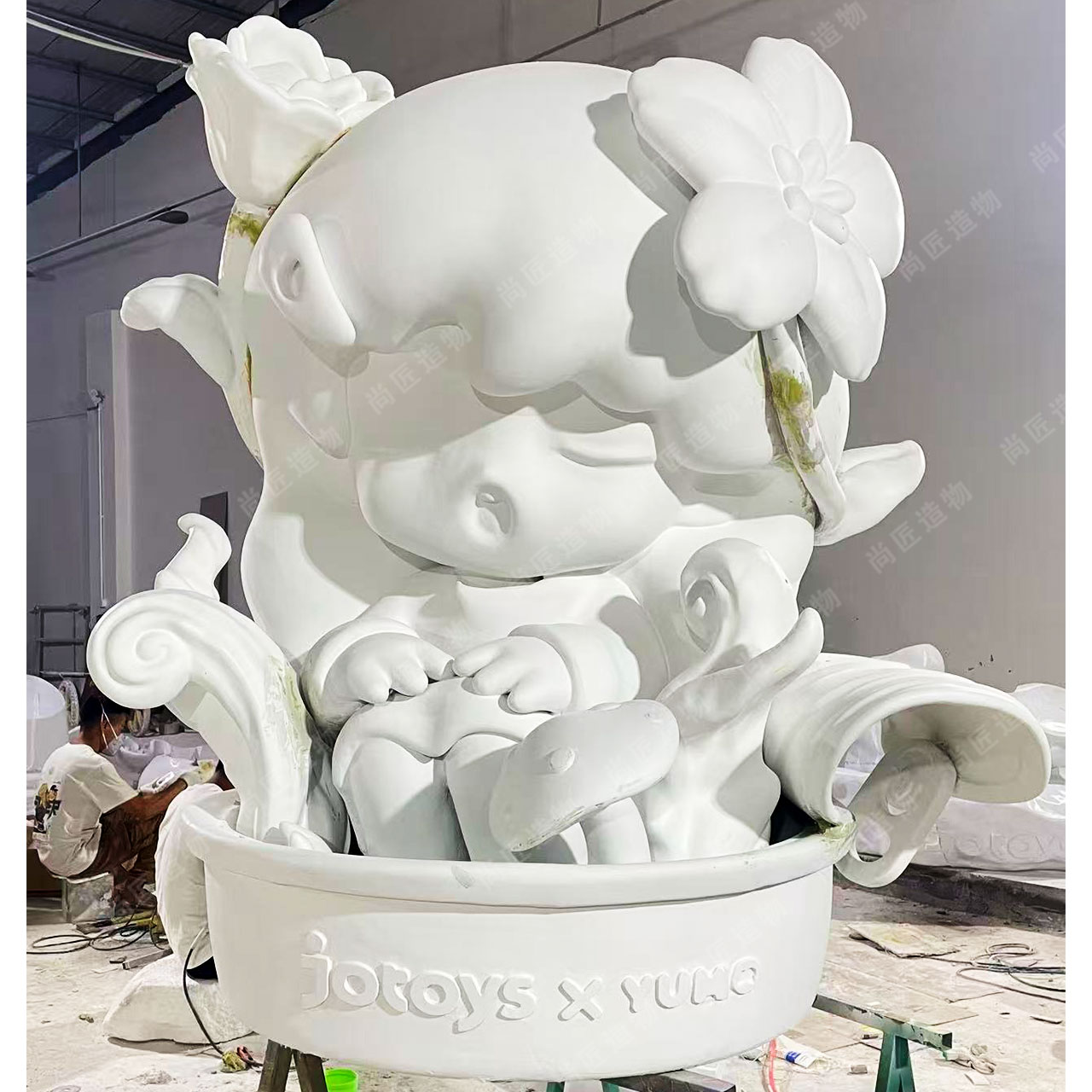

Transitioning merchandise designs into stainless steel sculptures begins with conceptual translation. Two-dimensional logos or product shapes must be reimagined as volumetric forms while preserving brand essence. Key considerations include simplifying complex graphics for structural integrity and identifying core visual elements that translate effectively to metal. Scale adjustments often reveal hidden opportunities—a beverage can tab motif might evolve into an architectural-scale arch when enlarged. During this phase, material properties directly influence design choices; stainless steel’s reflective surface naturally emphasizes curvature over intricate flat patterns.

"Successful adaptation distills merchandise DNA into its most elemental geometry—what remains must resonate without labels," notes public art consultant Mara Jenson.

Critical transformation factors include:

| Merchandise Feature | Sculpture Adaptation Approach |

|---|---|

| Printed Color Gradients | Textured Surfaces & Light Reflection |

| Flat Graphic Details | Strategic Negative Space Cutting |

| Product Proportions | Dynamic Scaling & Perspective Shifts |

| Motion Suggestions (https://en.artmovr.com/) Mechanics |

Material constraints become creative catalysts during this process. Thin support elements in original designs often transform into triangulated substructures, while vibrant colors convert to brushed or mirror-polished finishes. For merchandise implying movement—like rotating gears or fluttering tags—exploring kinetic sculpture principles maintains thematic continuity. Iterative prototyping with folded paper or wire models helps validate spatial relationships before metal fabrication begins, ensuring the artwork retains recognizable inspiration while functioning as standalone public art.

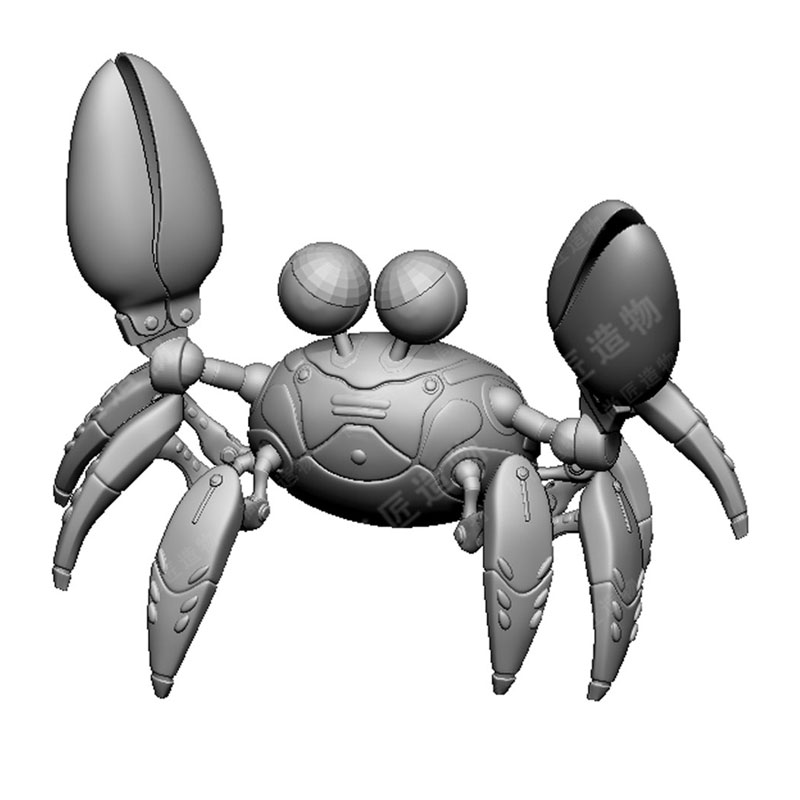

Adapting 2D Designs for Sculpture

Converting flat merchandise graphics into three-dimensional sculptures requires systematic reinterpretation. First, designers analyze the original artwork's key visual elements—identifying dominant shapes, negative spaces, and proportional relationships. This blueprint guides decisions about depth and volume. For example, a logo's thin lines might become folded steel ribbons, while solid color blocks translate into layered planes. Digital modeling software helps visualize these transformations, allowing adjustments for optimal structural integrity and viewing angles from all sides.

When translating branded characters or icons, maintaining recognizable silhouettes is essential. Complex designs often get simplified during this phase, removing intricate details that wouldn't withstand weathering or scale changes. Physical maquettes (https://en.artmovr.com/) projects. Material thickness calculations also begin here, anticipating how stainless steel's properties will affect the final form.

Stainless Steel Fabrication Methods

Translating merchandise designs into tangible, enduring sculptures requires selecting appropriate fabrication techniques for stainless steel. This stage involves transforming the adapted 3D model into a physical reality. Common methods start with precision cutting of sheet or plate material using plasma, laser, or waterjet systems to achieve the intricate profiles often derived from graphic logos or character outlines. Forming follows, where sections are shaped using techniques like rolling, bending (https://en.artmovr.com/). Post-welding, extensive grinding and polishing are employed to achieve the desired surface finish, remove weld marks, and ensure smooth contours that reflect light effectively. These fabrication choices directly impact the sculpture's final appearance, durability against weather, and resistance to vandalism. Ensuring the fabricated structure can withstand environmental loads and stresses necessitates close collaboration with structural engineers, moving the project into the next critical phase.

Structural Engineering for Artworks

Transitioning from fabrication to installation demands rigorous structural engineering. While stainless steel offers inherent strength and corrosion resistance, translating merchandise designs into permanent public installations introduces unique challenges. Engineers must analyze how the sculpture's form, derived from the original 2D concept, interacts with environmental forces. Key considerations include calculating dead loads, anticipating wind loads based on the artwork's profile and location, and assessing potential seismic activity. The base design is critical; it must provide sufficient stability, often requiring concrete foundations sized according to soil conditions and the sculpture's center of gravity. Connections between elements, whether welded or bolted, require careful detailing to handle stress concentrations, especially at transitions from the artwork to its support structure. Material thickness selection directly impacts both durability and the ability to resist deformation. Thorough engineering ensures the final stainless steel sculpture withstands decades of public exposure and use safely. This phase bridges the creative vision with the practical realities of permanent outdoor placement.

Site-Specific Sculpture Placement

Strategic placement transforms merchandise-inspired sculptures into cohesive public assets. Location analysis begins with evaluating pedestrian sightlines, ensuring optimal visibility from primary approach routes. Urban planners often collaborate with artists to assess how surrounding architecture complements the sculpture’s scale and reflective surfaces. For instance, positioning near glass-fronted buildings can amplify light interactions with polished stainless steel finishes. Environmental factors like prevailing wind patterns and salt exposure in coastal areas directly inform orientation choices. Community engagement further refines site selection—integrating sculptures near gathering spaces reinforces cultural relevance. The transition from studio to installation requires coordinating with civil engineers to verify subsurface stability, particularly for larger artworks requiring deep foundations. This groundwork naturally supports subsequent durability considerations for long-term public display. Thoughtful placement ensures these Realistic sculpture interpretations of commercial designs become enduring landmarks.

Durability in Public Art Installations

The transition from merchandise design to permanent public art fundamentally demands exceptional durability. Stainless steel excels in this critical aspect, offering inherent resistance to corrosion, weathering, and physical wear that surpasses many traditional sculptural materials. Unlike temporary or indoor display items, public installations face constant exposure to rain, snow, UV radiation, temperature fluctuations, and even accidental contact or vandalism. Selecting the appropriate grade of stainless steel, such as 304 or the more corrosion-resistant 316L for coastal or harsh industrial environments, forms the bedrock of longevity. Structural engineering considerations, integral to the fabrication phase, ensure the sculpture withstands wind loads, seismic activity, and its own weight over decades. This inherent toughness translates to significantly lower long-term maintenance costs compared to materials like painted mild steel or Fiberglass sculpture, which may require frequent repainting, repairs, or eventual replacement. Ultimately, the enduring nature of stainless steel guarantees that the transformed merchandise concept remains a vibrant and integral part of the public realm for generations.

Translating Graphics to 2D Forms

Moving a merchandise design from a flat image into a tangible sculpture requires thoughtful spatial interpretation. While the original graphic provides essential visual elements like shapes, logos, or patterns, translating these into three dimensions involves key decisions about depth, volume, and viewing angles. Typically, artists and designers employ two main approaches: extrusion or contouring. Extrusion involves pulling the 2D shape straight outwards to create depth, ideal for bold, iconic symbols. Contouring, on the other hand, involves building up layers or curves based on the graphic's lines to achieve a more organic, relief-like form, suitable for complex illustrations. This stage also determines the sculpture's scale and how material thickness impacts both the final appearance and structural integrity. Precise 3D modeling software is vital here, allowing for accurate scale projection and visualization of the form from all perspectives before fabrication begins.

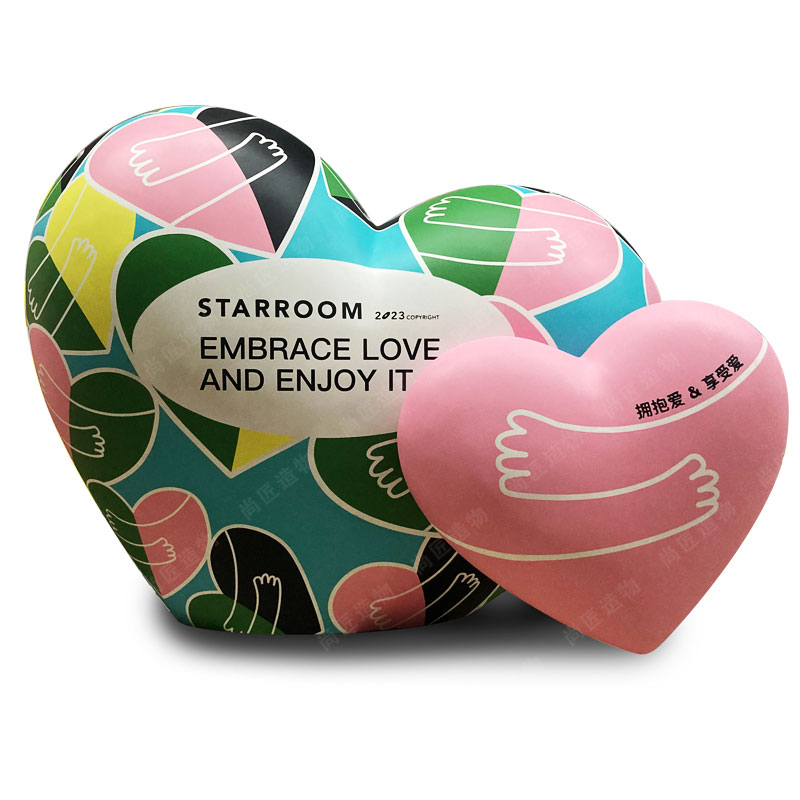

Surface Finishing Techniques Explained

The fabrication stage shapes the sculpture, but the final surface finish defines its visual character and long-term resilience. Selecting the right technique is crucial for translating the merchandise design's intent into durable public art. Common approaches for stainless steel include mechanical polishing, which can achieve anything from a subtle satin sheen to a high-gloss mirror finish, directly influencing how light interacts with the form and impacts visibility. Brushed finishes create distinctive linear textures, adding depth and masking minor surface imperfections effectively. For enhanced corrosion resistance, especially in harsh environments, passivation—a chemical treatment—removes free iron particles and strengthens the protective chromium oxide layer inherent to stainless steel. Colored finishes, applied through techniques like Physical Vapor Deposition (PVD), offer vibrant, fade-resistant options for specific branding elements. The chosen finish must balance aesthetic requirements, such as accurately reflecting the original merchandise's look and feel, with practical considerations like ease of maintenance and resistance to weathering, graffiti, and wear over decades of public exposure. This decision significantly impacts how the sculpture integrates visually within its site context.

Conclusion

Developing merchandise-inspired stainless steel sculptures represents a significant transformation from temporary graphic design to permanent public statement. This process demands careful consideration at every stage, from faithfully translating two-dimensional artwork into volumetric forms that retain brand identity, to selecting fabrication techniques ensuring structural integrity and longevity. The inherent durability and aesthetic versatility of stainless steel make it an ideal medium for installations exposed to public interaction and varying weather conditions. Ultimately, successfully integrating these sculptures into specific sites enhances community spaces, turning recognizable merchandise elements into enduring landmarks that engage viewers far beyond the product's original lifespan. Careful planning in engineering, finishing, and placement is paramount to achieve artwork that resonates publicly while withstanding the test of time.

Frequently Asked Questions

How long do stainless steel public sculptures typically last?

Properly fabricated and maintained stainless steel artworks can endure for 50+ years. The material's inherent corrosion resistance and protective finishes combat weathering effectively.

Can intricate merchandise graphics translate well into metal sculptures?

Yes. Modern techniques like waterjet cutting and CNC machining allow precise reproduction of complex 2D patterns. Strategic simplification during the 3D adaptation phase ensures visual clarity.

What maintenance do these installations require?

Minimal cleaning with mild soap and water suffices for most environments. Annual inspections check for structural integrity, fastener tightness, and surface integrity, especially in coastal or high-pollution areas.

Are merchandise-inspired sculptures vulnerable to vandalism?

Stainless steel's hardness resists scratching better than softer metals. Anti-graffiti coatings can be applied during finishing, enabling easier removal of unwanted markings without damaging the artwork.

How are large sculptures anchored securely at installation sites?

Engineered concrete foundations with stainless steel embed plates provide stability. Site-specific factors like soil composition, wind load calculations, and seismic activity determine the anchoring system's design depth and configuration.

Can original merchandise colors be replicated on metal sculptures?

Through advanced powder coating or PVD (Physical Vapor Deposition) finishes, vibrant and durable color matching is achievable. These coatings also enhance UV resistance and longevity.

ch

ch English

English