Key Takeaways

- Strategic site selection balances artistic visibility with environmental factors like wind patterns and soil stability, ensuring the sculpture's integrity and motion.

- Robust fiberglass anchoring systems counter wind forces, utilizing specialized foundations and hardware designed for kinetic stress and material flexibility.

- Prioritizing public interaction safety involves integrating smooth, durable moving parts, protective barriers where needed, and clear viewing zones.

- Advanced weatherproof mounting techniques protect connections and electrical components from moisture, UV damage, and temperature fluctuations.

- Proactive long-term maintenance protocols are essential, involving regular inspections of moving mechanisms, structural joints, and surface coatings.

- Optimized interactive component placement considers ergonomics, accessibility for diverse users, and resilience against frequent public engagement.

- Durable fiberglass anchoring solutions specifically address the material's unique properties, preventing stress fractures and material fatigue over time.

- Comprehensive protection strategies shield the sculpture from environmental elements, including specialized sealants and drainage considerations.

Soil testing before installation is non-negotiable; understanding ground composition prevents costly foundation issues later.

Selecting Park Sites for Kinetic Sculptures

Strategic placement of fiberglass kinetic sculptures directly impacts their functionality and longevity. Three primary factors guide optimal site selection: wind exposure, ground stability, and visitor flow patterns. Areas with consistent wind currents activate sculptures naturally but require careful assessment of gust patterns. Stable, level terrain prevents structural shifting, while proximity to pathways ensures visibility without obstructing pedestrian movement.

| Selection Factor | Ideal Conditions | Risk Considerations |

|---|---|---|

| Wind Exposure | Moderate, predictable breezes | Avoid wind tunnels or vortex zones |

| Ground Composition | Compact soil or bedrock | Loose soil requires deeper foundations |

| Visitor Access | Near main paths (15-20 ft clearance) | High-traffic zones need safety buffers |

Sites near water features or wooded areas often create microclimates affecting motion patterns. Municipal art coordinators should consult historical weather data and conduct soil tests before installation. For comparison, anchoring requirements differ significantly from static artworks like stainless steel sculptures. This preliminary evaluation establishes the foundation for subsequent wind-resistance measures while maximizing interactive potential.

Securing Fiberglass Against Wind Forces

Wind exposure presents significant challenges for kinetic sculptures in open park environments. Fiberglass components, while lightweight and versatile, require specialized anchoring systems to withstand sustained gusts and storms. Engineers typically recommend embedding structural supports into concrete foundations that extend below frost lines—this prevents uplift forces from compromising stability. For sculptures exceeding eight feet, cross-bracing with corrosion-resistant steel tendons distributes lateral pressure across the framework. Computational fluid dynamics modeling helps predict wind load patterns specific to each installation site, informing strategic reinforcement points. Regular torque checks on anchor bolts should be integrated into maintenance schedules, as vibration from movement can gradually loosen connections. Properly secured fiberglass sculpture elements maintain structural integrity while allowing designed motion ranges, creating a reliable base for public interaction features discussed next.

Ensuring Public Interaction Safety

Safety remains paramount when integrating interactive kinetic sculptures into public parks. Following strategic site selection and secure anchoring against wind forces, attention shifts to managing direct public engagement. Establishing a clear safety buffer zone around the sculpture is essential. This perimeter, often subtly defined using low-profile ground markings or textured paving, prevents accidental contact during the sculpture's movement cycles, particularly important for larger pieces. Materials chosen for interactive elements must be exceptionally durable and impact-resistant, such as reinforced fiberglass composites, to withstand frequent public touch and potential impacts. Simultaneously, designers must ensure all moving parts are completely enclosed or positioned out of reach, eliminating pinch points. Furthermore, pathways must remain unobstructed, guaranteeing clear sightlines for viewing the sculpture's motion while maintaining full accessibility for all park visitors, including those with mobility aids. This layered approach minimizes risks while preserving the artwork's interactive appeal. For examples of durable materials used in public art, consider exploring Realistic sculpture.

Weatherproof Mounting Methods Explained

Proper weatherproofing begins with selecting marine-grade stainless steel hardware for all anchoring points, which inherently resists corrosion from rain and humidity. For fiberglass kinetic sculptures, we recommend epoxy-sealed expansion anchors that create watertight seals within concrete foundations while accommodating natural material expansion. Critical attention must address drainage paths around baseplates; even slight water pooling accelerates deterioration. Applying UV-resistant gel coats during installation forms an essential protective barrier against sun damage, complementing the structural integrity of the kinetic sculpture. All electrical components for interactive features require waterproof conduit systems rated for outdoor submersion, with junction boxes elevated above flood-risk levels. Periodic sealant renewal at joint interfaces—typically every 18 months—prevents moisture ingress that could freeze and crack fiberglass during winter months. These measures collectively ensure decades of reliable operation despite seasonal extremes.

Long-Term Kinetic Sculpture Maintenance

Beyond initial installation, establishing a consistent maintenance schedule is crucial for preserving the functionality and appearance of fiberglass kinetic sculptures in public parks. Regular inspections, ideally biannual, form the cornerstone of effective upkeep. These checks should focus on verifying the structural integrity of all moving parts, examining joints and bearings for signs of wear or corrosion, and ensuring anchoring systems remain secure. Fiberglass surfaces require periodic cleaning with mild, non-abrasive solutions to remove environmental buildup like dirt, pollen, and bird droppings, which can degrade finishes over time. Applying specialized UV-protective coatings every few years is essential to combat sun damage and prevent fading or brittleness in the composite material.

Lubrication of moving components, using products resistant to weather and dust, must be performed according to the manufacturer's specifications to maintain smooth, silent operation. While kinetic sculptures demand specific attention to mechanics, some principles, like routine surface care, apply broadly to diverse public art installations, including durable Cartoon sculpture. Monitoring for stress cracks or impact damage, particularly after severe weather events, allows for prompt repairs. Documenting all maintenance activities provides valuable records for predicting future needs and budgeting. This proactive approach ensures the sculpture continues to provide a safe, dynamic visual experience for park visitors for decades. Equally critical is the strategic placement of interactive elements to maximize engagement and durability.

Optimizing Interactive Component Placement

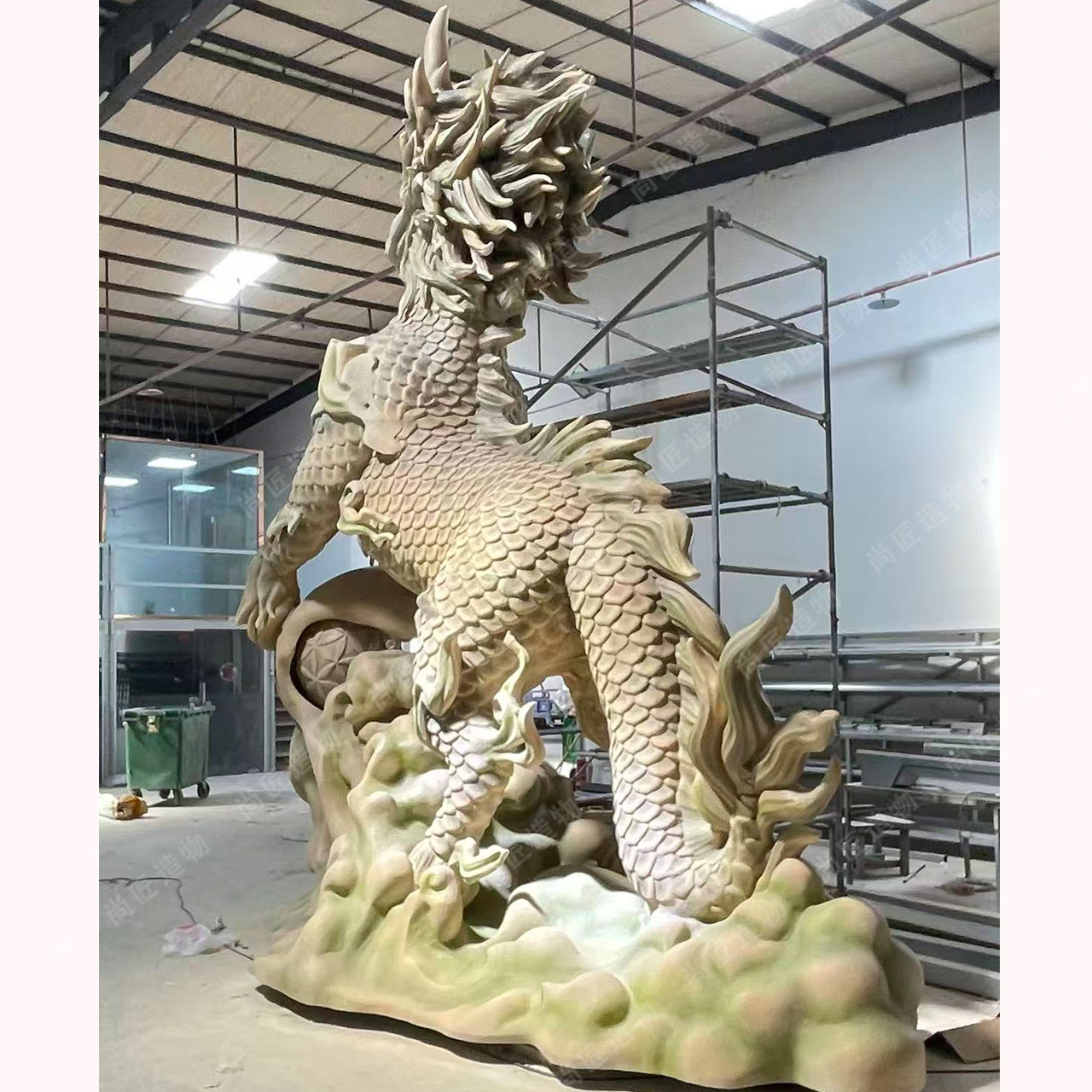

Strategic placement of interactive elements significantly enhances both accessibility and kinetic performance. Position components at varying heights between 24-48 inches to accommodate children and wheelchair users, while maintaining clear sightlines for supervision. Ensure moving parts operate within a 60-degree arc to prevent collisions with fixed structures or vegetation identified during site selection. For sculptures featuring character designs like IP character sculpture, orient interactive levers or wheels perpendicular to prevailing wind patterns to reduce resistance. Additionally, install touch surfaces at least 12 inches from primary motion axes to eliminate pinch points, aligning with previously discussed safety protocols. Test all interactive mechanisms under maximum visitor load scenarios before final anchoring, verifying that engagement doesn't compromise structural stability established through fiberglass mounting systems.

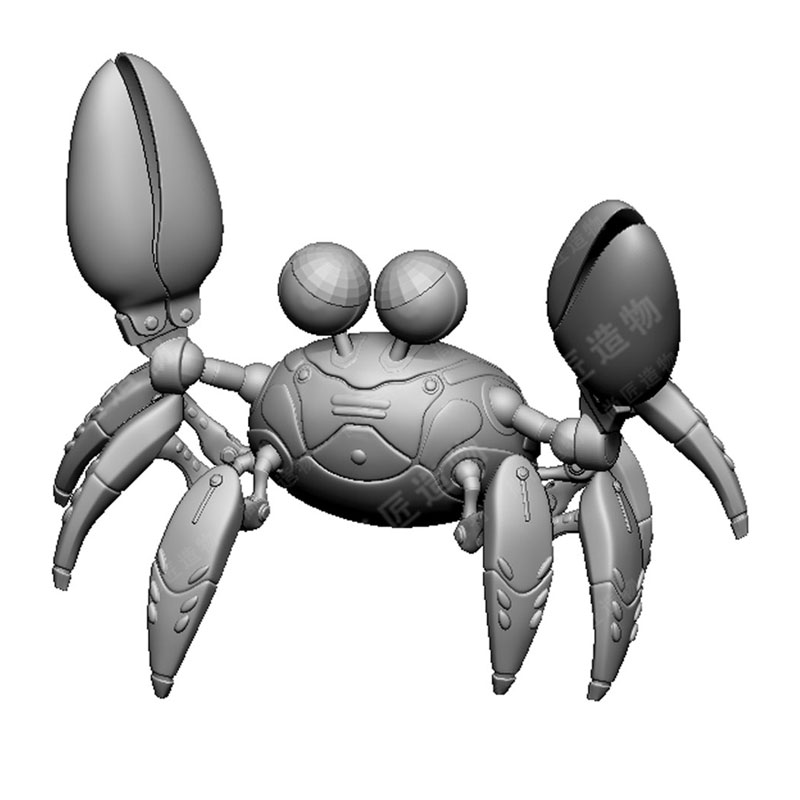

Durable Fiberglass Anchoring Solutions

Therefore, establishing a robust foundation is critical for the longevity and stability of fiberglass kinetic sculptures exposed to outdoor forces. Selecting the appropriate anchoring system depends heavily on the sculpture's size, weight distribution, and the specific soil conditions at the installation site. For most permanent park installations, embedding heavy-duty, corrosion-resistant steel anchors into substantial concrete footings provides the highest level of security against wind uplift and ground movement. These anchors securely connect to the sculpture's internal structural framework, typically made of stainless steel or similarly resilient materials integrated within the fiberglass shell. Ensuring a tight, vibration-resistant connection point prevents stress fractures in the fiberglass over time. Meanwhile, using galvanized or epoxy-coated anchor hardware protects against rust, a key factor in maintaining the anchor's integrity for decades and preventing premature failure. Proper installation depth and concrete curing times are non-negotiable steps for achieving the necessary holding power.

Protecting Sculptures from Elements

Beyond securing sculptures against wind forces, environmental protection requires proactive measures against moisture, temperature changes, and ultraviolet radiation. Fiberglass components benefit significantly from marine-grade gel coats applied during fabrication, creating a resilient barrier against water absorption and freeze-thaw damage. For existing installations, specialized UV-inhibiting sealants should be reapplied every 18-24 months to prevent color fading and surface micro-cracking. Drainage design proves equally critical; sloping bases and concealed runoff channels prevent water accumulation near moving parts, reducing corrosion risks in mechanical joints. Thermal expansion gaps must be maintained around anchor points to accommodate material contraction during winter months. These combined strategies preserve structural integrity while ensuring interactive mechanisms operate smoothly across seasonal variations. Regular inspection of protective coatings remains essential, particularly after extreme weather events that could compromise surface treatments.

Conclusion

Installing fiberglass kinetic sculptures in parks requires careful planning at every stage. From choosing the right location to securing components against weather, each step contributes to long-lasting functionality. Proper anchoring prevents wind damage while interactive elements must remain accessible and safe for public enjoyment. Regular maintenance checks ensure moving parts operate smoothly year after year. When executed correctly, these dynamic artworks become valuable community assets. They transform ordinary park spaces into engaging environments where art and nature interact. The effort invested in installation pays off through enduring visual interest and meaningful public experiences. Following the outlined procedures creates sculptures that withstand environmental challenges while inviting ongoing visitor interaction.

FAQs

What is the minimum space needed for kinetic sculptures in parks?

Adequate clearance is essential; allow at least 15 feet radius around moving components to ensure safe interaction paths and accommodate full motion range.

How are fiberglass kinetic sculptures anchored against strong winds?

Engineered concrete foundations with stainless steel rebar cages are standard, often coupled with ground anchors or helical piles depending on soil stability and wind load calculations.

Are interactive kinetic sculptures safe for children?

Yes, when designed with rounded edges, non-pinching mechanisms, and sensors limiting force. Regular safety audits of moving parts and touch surfaces are mandatory.

What protects these sculptures from rain and UV damage?

High-gelcoat fiberglass resists moisture, while UV-inhibiting resin coatings prevent fading. All internal mechanics receive waterproof enclosures and corrosion-resistant coatings.

How often should moving parts undergo maintenance?

Schedule professional lubrication and component inspection quarterly, with detailed structural assessments annually before peak seasons to ensure optimal function and safety.

ch

ch English

English